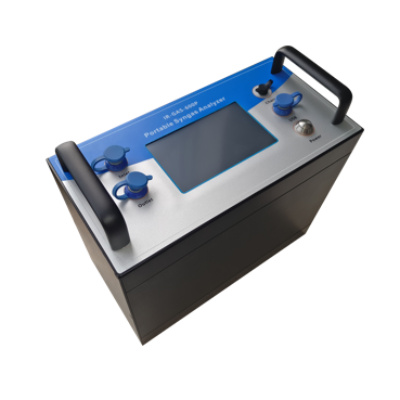

H2S Laser Gas Analysis System

- Product Item : eLAS-600Ex

- Category: Laser Gas Analysis System

- Laser Technology

- H2S gas analyzer

- Gas Analyzer

- H2S

Introduction

The H2S on-line monitor system eLAS-600Ex continuously monitor the H2S in the industrial production process. The system including sample gas sampling and transmission parts, pretreatment parts and analysis unit . The sample gas enters the analyzer through the sampling pipeline, and enters the gas chamber of the analyzer for detection and analysis after dedusting and dehumidification according to the characteristics of the sample gas.

TDLAS Technology (tunable diode laser absorption spectroscopy) is used in the analyzer, which is one of the most advanced gas measurement methods in the world at present. The instrument has the characteristics of high sensitivity, fast response, free from background gas interference and non-contact measurement, providing a reliable guarantee for real-time and accurate reflection of H2S change.

Applications

process control/explosion pre-warning monitoring

environmental flue gas emission monitoring

boiler combustion control

air separation and gas production

aerospace, electric power, electronics, biological technology and scientific research institutions, etc

Specifications

|

Measured gas |

HCL/HF |

|

Method |

Tunable Diode Laser Spectrometry (TDLS) |

|

Range |

HCL/HF: 0-50ppm,0-100ppm,0-500ppm( Customized) |

|

Accuracy |

± 1% full scale reading depending on integration stability (temperature & pressure) |

|

Precision |

1ppm |

|

Displayed resolution |

0.1ppm |

|

Response time |

Less than 15S (at gas flow rate of 3 L/min) |

|

Sampling Gas Temperature |

≥180℃ |

|

Analog Output |

4`20mA DC, Insulating output, maximum load is 900 ohm, |

|

Digital Output |

RS232/485 |

|

Power Supply |

90-240VAC / 50/60Hz 120W |

|

Warm up time |

30 minutes |

|

Interface |

RS485 |

|

Ambient Temperature |

Temp:-10-50℃ Humidity:0-90%RH |

|

Dimension |

758(L)*500(W)*255(H)mm

Weight : 60kgs

|