Continuously Emission Monitoring System

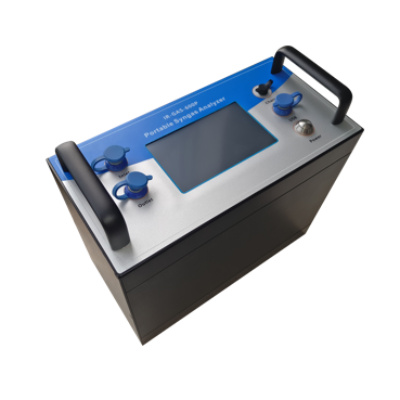

- Product Item : EM-GAS-500

- Category: CEMS Monitoring System

- Flue Gas Analysis

- UV technology

- Measure CO,CO2,SO2,NO,NO2

Continuously Emission Monitoring System

Introduction

The Continuous Emission Monitoring System (CEMS) EM-GAS-500 developed and produced by ESE is to monitor the total air pollutant emissions from stationary sources, mainly used for industrial boilers, power plant boilers, industrial furnaces emissions monitoring, SO2, NO,NO2, O2,CO,CO2,HCL,HF, H2O etc dynamic continuous monitoring, simultaneous to measure gas flow, oxygen content, gas pressure, gas temperature, gas humidity etc, automatically recording the total pollutant emissions volume and emission time.

Applications

Chloralkali plant PVC process ,Titanium white production process ,Sulfur recovery process ,Natural gas purification process ,Methyl iodide analysis for the coal chemical industry ,On-line air monitoring ,Coal-fired power plants ,Cement plant ,Industrial furnaces , desulfurization process monitoring ,Denitration process monitoring , Incinerators

Features

- The system can automatic sampling, remove dust, calibration, fault diagnosis and alarm.

- System cabinet modular design, simple operation, less maintenance.

- System by heating extraction method for continuous monitoring of flue gas pollutants.

- The sampling probe has big filter area, and filter easy to change.

- The pretreatment device is effectively waterproof and dust proof, anti-corrosion and anti-clogging.

- The stability and reliability of the system are higher by PLC design.

- System has a variety of data output.

Components

Particulates measurement subsystem

1)particulates concentration sensor

2)particulates concentration calculation unit (secondary instrument)

3)air purification system or air purge system

Emission gases measurement subsystem (including oxygen)

1)sampling Probe

2)gas pretreatment unit

3)gas control unit

4)calibration standard gases

5)SO2, NOX, O2 analyzer,HCL,HF,VOC(optional)

6)gas supply system (back flushing unit, zero gas unit)

7)heated tube

Gas conditions measurement subsystem

1)gas flow meter

2)gas pressure measuring instrument

3)gas temperature measuring instrument

4)gas humidity measuring instrument

Data acquisition and processing system

1)IPC

2)display

3)software